Product Details

The sawdust tray forming hydraulic press developed by Zhongyou Heavy Industry Machinery Co., Ltd. is specifically designed to support the forming of trays using biomass materials such as sawdust and sawdust. The equipment adopts advanced hydraulic drive system, combined with CNC control technology, with stable pressure, high forming efficiency, and simple operation. It is equipped with large CNC machined parts, made of high-quality equipment and wear-resistant materials, to ensure long service life and reliable operation of the equipment. The multi-level temperature control heating system effectively ensures that the wood chip material is fully hot pressed into shape, and the finished product has high strength and strong moisture resistance. The wood chip tray forming hydraulic press supports customized design, adapts to the production needs of different specifications of tower frames, and is widely evaluated in logistics, warehouse and other fields.

I. Raw material preparation

Choose suitable raw materials, such as wood shavings, plant straw and so on. Preliminary processing of raw materials, including cutting, chipping and other steps for subsequent crushing and mixing.

2, crushing and mixing

The preliminary processed raw materials are crushed to the appropriate particle size and automatically proportioned for transfer as required.

Mixing of the proportioned raw materials with adhesives. The mixing process should ensure that the adhesive is evenly distributed in the raw material to improve the strength and stability of the pallet.

3, drying and cooling

The mixed raw materials are dried at high temperature to reduce their moisture content to ensure the stability and quality of the pallet in the moulding process.

After drying, the raw material should be cooled for subsequent moulding operations.

4.Moulding

The dried and cooled mix is conveyed to the laying machine in set quantities. The spreader spreads the mix evenly in the mould in preparation for moulding.

A hydraulic press for wood chip pallets is used to apply high temperature and pressure to the mix in the mould. The hydraulic press provides a strong compressive force that binds and cures the mix in the mould.

After moulding, the pallet is automatically removed from the mould.

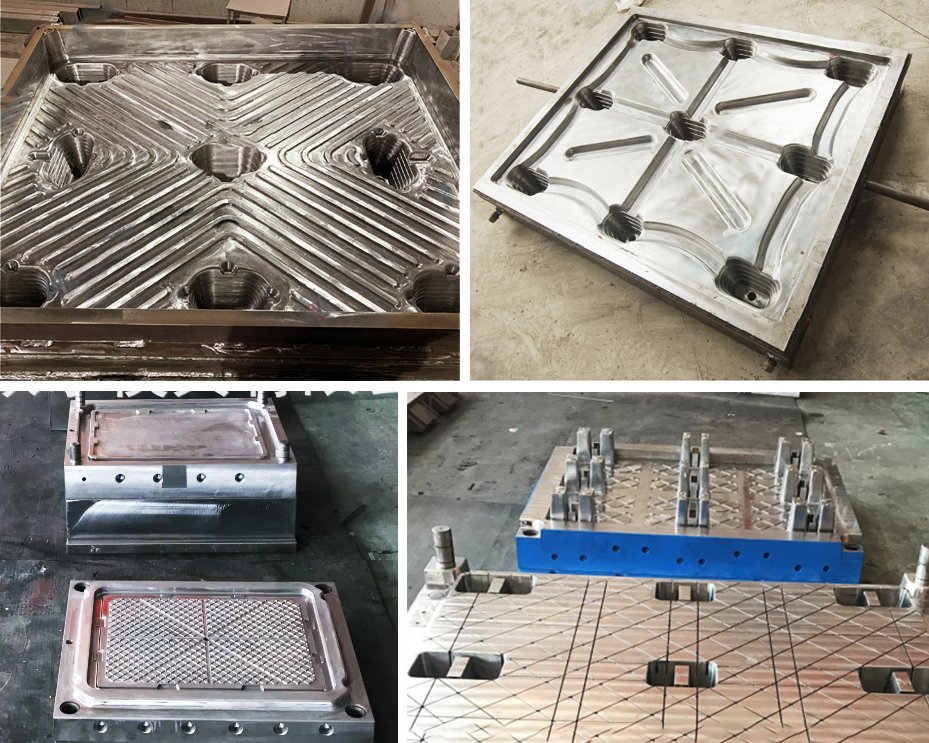

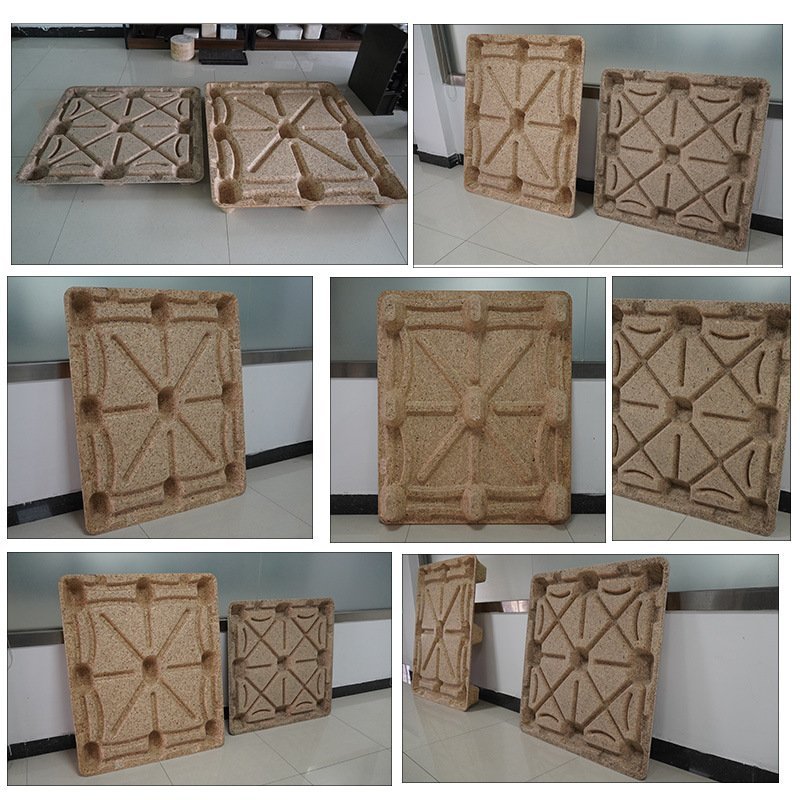

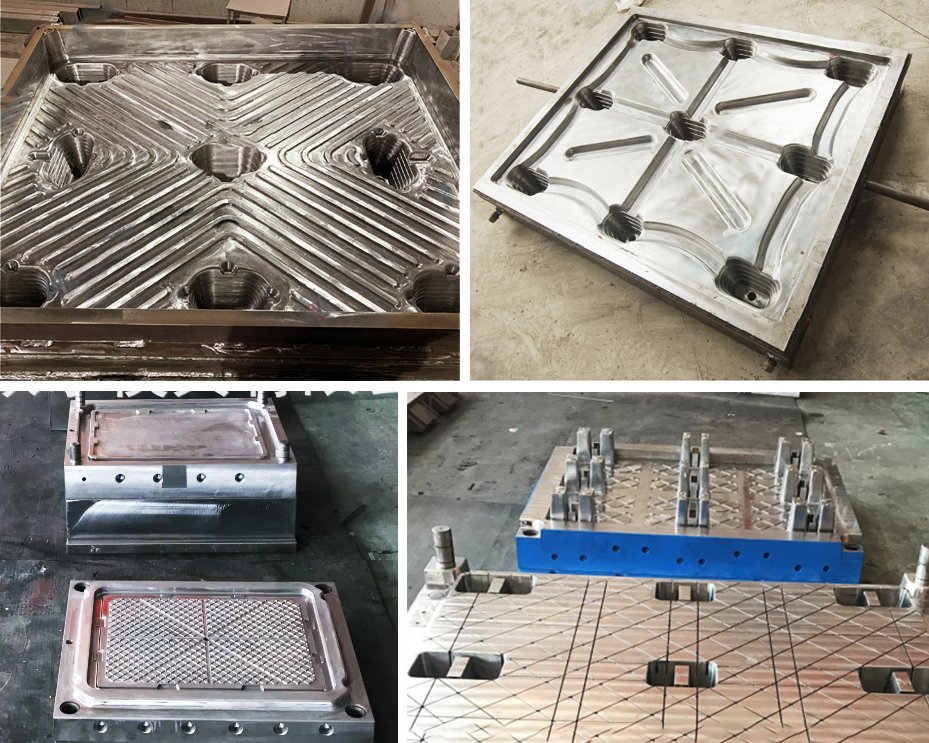

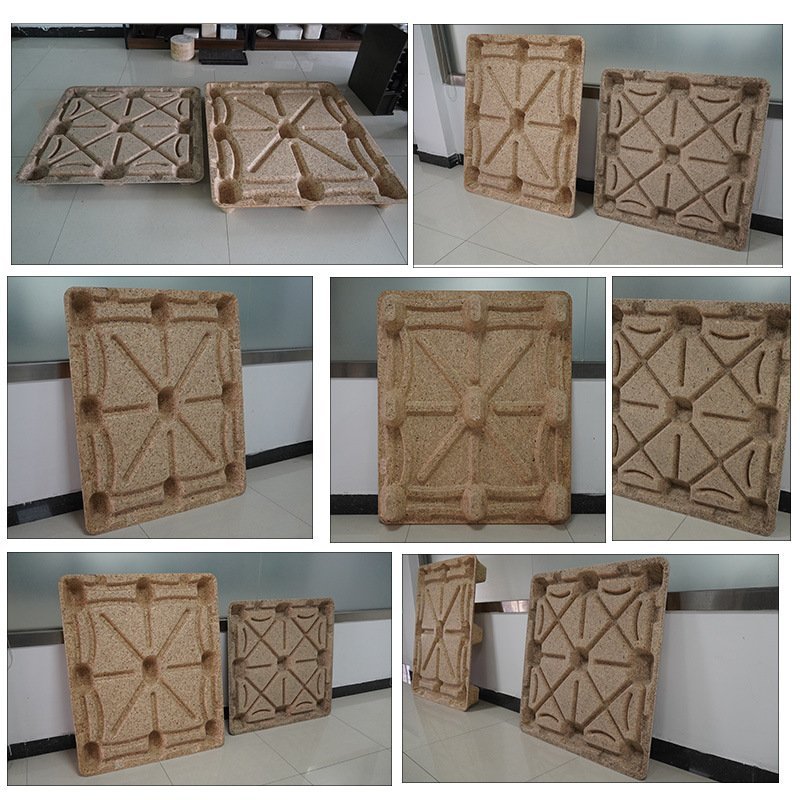

Mold

Molded pallet hot press is a new type of molded pallet production equipment, the use of hot pressing process of one-time molding, pallet hydraulic press has the advantages of high efficiency, one-time molding, material saving, high strength, environmental protection and energy saving.

Depending on the size of the pressed pallet flower pattern, can be configured with different molds, specific can consult customer service.

Application Cases

Application Cases

Customer Cases